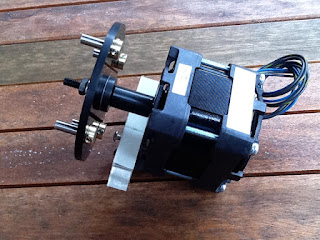

The finished article looks really good.

The two perspex blocks used to mount the motor have the cut sides polished. This is an extra service offered by Trent Plastics when you order any pieces of perspex. It's only a couple of quid extra and really adds a finishing touch.

The brass disc fitted to the back of the rotor disc provides electrical contact between the four tungsten rods. It has the centre removed to isolate it from the motor shaft. It's a 2mm thick brass disc of 100mm diameter with a central cut out of 40mm diameter. It was made by http://www.ringwoodprecision.com/ all I had to do is drill out the 4 1/4" holes for the tungsten rods.