Have now had my secondary coil mounted in the winding jig for a couple of weeks. It seems to be taking ages to get the correct amount of anti tracking varnish on the coil. I have just applied the forth coat.

I have applied each coat by brush with the winding jig rotating at about 5rpm. It's a good way of holding the coil while its being varnished plus the rotation helps prevent runs from forming. As you can see after coat number 4 the coil seems to have a gloss finish. However on closer inspection.....

.....you can see there are still areas that have not been been completely covered by varnish. I have ordered another bottle of varnish which should give me another 2 layers which, hopefully, will give the full gloss cover over the whole coil.

I've noticed that you can still feel the individual turns in the areas that are not fully covered so I think I will use the rule that when it feels smooth it's got enough coats.

This is my blog of current hobbies, at the moment that happens to be all things Tesla so I have decided to build a Tesla coil and, as usual, I will go completely over the top with it.

Showing posts with label winding secondary. Show all posts

Showing posts with label winding secondary. Show all posts

Tuesday, 25 October 2011

Sunday, 16 October 2011

Winding the Secondary Coil

Now that the toroid has finally arrived I am keen to finish off the secondary coil so I can progress on to the primary. The next step is to wind the secondary. The windings will be as per the instructions, 26awg wire which is 0.40mm diameter. When measured with my verniers I get an average of 0.44mm which (I presume) is due to the insulating varnish coating on the wire. The wire will be wound onto my 6" perspex form which measures 810mm. The windings will be 28" high centred on the perspex tube. I will be using my recently upgraded (now motorized) winding jig.

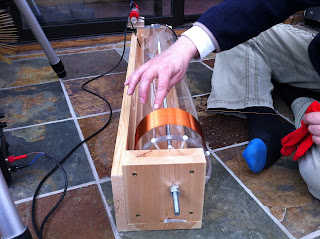

Above you can see the coil former fitted on to the jig. I calculated that there would be just over 1600 turns on the coil each single turn being 471mm (150mm X 3.141) so a total length of 753 metres of wire!

The winding jig is geared to turn at 15rpm running at a maximum 12 volts so 1600 turns would take 106 minutes minimum.

I started the winding by passing the wire through 3 tiny holes, first in then out then back inside the former, leaving about 6" inside to work with. With the motor running I started to lay down the first few turns. I used my left hand to guide the wire onto the form and a finger nail on my right hand to keep the coils pushed up against each other (if needed). I soon realised that 15rpm was a little fast and backed the bench supply back to 10 volts. Also this is definitely easier as 2 person job. I needed my son (Damien) to help make alterations to rpm, stop and start the jig when the turnings accidently overlap, reposition the feed spool and countless other help during what turned out to be 3 hours of boredom occasionally broken up with moments of intense panic.

The pic above shows the finger nail guide technique which proved to be quite successful. In my left hand you can see a piece of material which I used to create a bit of tension on the wire.

It's best to feed the wire onto the coil slightly behind the present position on the former. This means the last coil on the tube helps guide on the next turn.

Here's a quick video that shows a little of the winding process. Sorry about the annoying noise the winding jig makes. We had to listen to it for 3 hours so think yourself lucky!

Above you can see the coil former fitted on to the jig. I calculated that there would be just over 1600 turns on the coil each single turn being 471mm (150mm X 3.141) so a total length of 753 metres of wire!

The winding jig is geared to turn at 15rpm running at a maximum 12 volts so 1600 turns would take 106 minutes minimum.

I started the winding by passing the wire through 3 tiny holes, first in then out then back inside the former, leaving about 6" inside to work with. With the motor running I started to lay down the first few turns. I used my left hand to guide the wire onto the form and a finger nail on my right hand to keep the coils pushed up against each other (if needed). I soon realised that 15rpm was a little fast and backed the bench supply back to 10 volts. Also this is definitely easier as 2 person job. I needed my son (Damien) to help make alterations to rpm, stop and start the jig when the turnings accidently overlap, reposition the feed spool and countless other help during what turned out to be 3 hours of boredom occasionally broken up with moments of intense panic.

The pic above shows the finger nail guide technique which proved to be quite successful. In my left hand you can see a piece of material which I used to create a bit of tension on the wire.

It's best to feed the wire onto the coil slightly behind the present position on the former. This means the last coil on the tube helps guide on the next turn.

Here's a quick video that shows a little of the winding process. Sorry about the annoying noise the winding jig makes. We had to listen to it for 3 hours so think yourself lucky!

We have done a longer video which Damien is going to process and convert into a time lapse. We will post it to youtube and stick a link in here when it's done.

Three hours later and the coil was finished. Could help sticking it in place with the toroid just to get an idea of the finished TC.

Damien's arty shot. We are about to decorate so no comments on the pink flowery wall paper please.

If you like this blog you can show your support by one or all of these.

1. Click on some ads shown on this blog.... I get paid for that.

2. Follow me.... It's good to know someones interested.

3. Leave a comment.... All are appreciated.

Sunday, 9 October 2011

Winding Jig Upgrades

I finished the secondary coil winding jig a few weeks back and was planning to wind the coil by spinning the perspex tube by hand. After deciding to upgrade to a 6" coil and reading lots more winding stories on the web I have decided to upgrade my jig by adding a motor.

The picture above shows the finished winding jig in its manual mode to speak. The easiest way to rotate the secondary coil would be to drive it directly with a rubber drive belt otherwise I would have to drive the central shaft and fix the perspex former to it. Direct drive to the coil tube via rubber belt was chosen and the parts quest was on.

I would need a motor with a suitable gearbox, a pulley to fit the output shaft and a rubber drive belt. First place I tried was Maplin, I had bought a similar motor from there in the passed to power the belt on a Van der Graaf generator I made. They had the motor I needed but not the belt or a suitable pulley so I carried on looking. I found everything I needed at Technobots they had an excellent choice of motors, pulleys and drive belts, they took Paypal and delivered the stuff within a few days. I was aiming for a coil rotational speed of around 15rpm so a bit of maths was needed to work out gearbox ratio, pulley size and drive belt diameter. Final positioning of the motor on the jig is really by trial and error, you just need to get the right tension on the drive belt so it doesn't slip as you are winding. I had to mount the motor on a small piece of wood to get the correct spacing.

The motor I used was a 540 size motor that came with a 148:1 reduction gearbox. The mounting plate comes with it, the output shaft is 6mm and it can be run on 4.5v to 15v.

I needed to make a small cut out on the back panel of the jig to allow clearance for the drive belt. The upgrade was finished and it went quite well to say that I hadn't designed the jig to take a motor to start with.

I also knocked together a spool support for the 26awg wire. This would need to allow the feed spool to rotate freely so I did my typical over engineering on it. Starting with an old piece of wood and a length of 10mm aluminium rod.

I had a sealed bearing with a 10mm ID to hand so I turned a 10mm ID X 16mm OD 3mm spacer which went onto the 10mm vertical aluminium shaft followed by the bearing.

Then another 10mm ID X 16mm OD spacer, this time 15mm deep.

Then the spool itself then another spacer/bush to keep the top of the spool centred. Doesn't look pretty but works very nicely.

The picture above shows the finished winding jig in its manual mode to speak. The easiest way to rotate the secondary coil would be to drive it directly with a rubber drive belt otherwise I would have to drive the central shaft and fix the perspex former to it. Direct drive to the coil tube via rubber belt was chosen and the parts quest was on.

I would need a motor with a suitable gearbox, a pulley to fit the output shaft and a rubber drive belt. First place I tried was Maplin, I had bought a similar motor from there in the passed to power the belt on a Van der Graaf generator I made. They had the motor I needed but not the belt or a suitable pulley so I carried on looking. I found everything I needed at Technobots they had an excellent choice of motors, pulleys and drive belts, they took Paypal and delivered the stuff within a few days. I was aiming for a coil rotational speed of around 15rpm so a bit of maths was needed to work out gearbox ratio, pulley size and drive belt diameter. Final positioning of the motor on the jig is really by trial and error, you just need to get the right tension on the drive belt so it doesn't slip as you are winding. I had to mount the motor on a small piece of wood to get the correct spacing.

The motor I used was a 540 size motor that came with a 148:1 reduction gearbox. The mounting plate comes with it, the output shaft is 6mm and it can be run on 4.5v to 15v.

I needed to make a small cut out on the back panel of the jig to allow clearance for the drive belt. The upgrade was finished and it went quite well to say that I hadn't designed the jig to take a motor to start with.

I also knocked together a spool support for the 26awg wire. This would need to allow the feed spool to rotate freely so I did my typical over engineering on it. Starting with an old piece of wood and a length of 10mm aluminium rod.

I had a sealed bearing with a 10mm ID to hand so I turned a 10mm ID X 16mm OD 3mm spacer which went onto the 10mm vertical aluminium shaft followed by the bearing.

Then another 10mm ID X 16mm OD spacer, this time 15mm deep.

Then the spool itself then another spacer/bush to keep the top of the spool centred. Doesn't look pretty but works very nicely.

Subscribe to:

Posts (Atom)